- Producing green composite sinks and worktops by reusing offcuts and production wasteone of Delta sinks

- Delta presents the LIFE GREEN COMPOSITE project to the 2022 beneficiaries of the LIFE programme!

- Project Objective

- How the Project Objective will be Achieved

- New Industrial Plants

- Innovations

- Interviews on recovery and circular economy

- Downloadable material

- Picchio News published a press release on the LIFE GREEN COMPOSITE project 'The Plados-Delta group will be the first company in the world to produce a range of 'green' sinks'

- LAYMAN'S REPORT

- FINAL RESULTS OF THE PROJECT

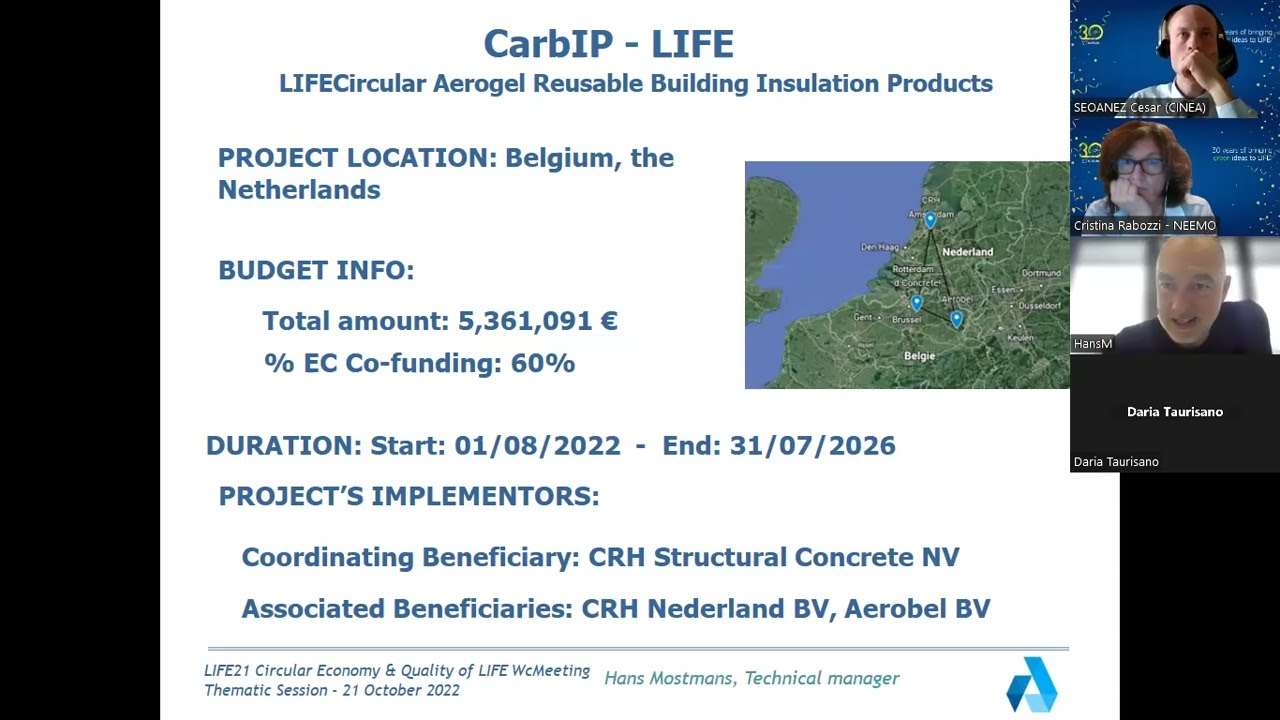

Project co-funded by the European Unione LIFE21-ENV-IT-LIFE GREEN COMPOSITE

PROJECT DURATION: Start 01/08/22 - End 31/07/25

Coordinating Beneficiary: DELTA Srl

Associated Beneficiary: GEES RECYCLING Srl

Project location: Montelupone - Montecassiano (Macerata / Pordenone) Italy

On 1 August 2022 Delta of Plados Telma group started the LIFE project in cooperationone with Gees Recycling, a project co-funded at 60% by the European Commission.

The project will run for three years, ending on 31 July 2025.

Producing green composite sinks and worktops by reusing offcuts and production wasteone of Delta sinks

The production of sinks involves the landfilling of large quantities of polymer-contaminated mineral waste. This project aims to demonstrate that mineral composite sinks can be produced on a pilot and industrial scale by reusing acrylic mineral composite waste and producing these composites from secondary raw materials. The process, which will include new products, should confirm that all sink waste can be recycled. We will promote our GREEN composite production line to consumers by introducing a new product range to the market.

Project contact: Dr. Maria Savina Pianesi e-mail: savina.pianesi@pladostelma.com

Delta presents the Life GREEN COMPOSITE project

to the 2022 beneficiaries of the LIFE programme!

You can download the Powerpoint of presentazione.

Project Objective

New green composites: GREEN WORKTOP and GREEN KITCHEN SINKS

The project will exploit the industrial symbiosis between Plados Telma (Coordinator) and Gees Recycling to produce green kitchen sinks and worktops: acrylic mineral composites made from recycled production waste and tracked in a replicable circular value chain

How the Project Objective will be Achieved

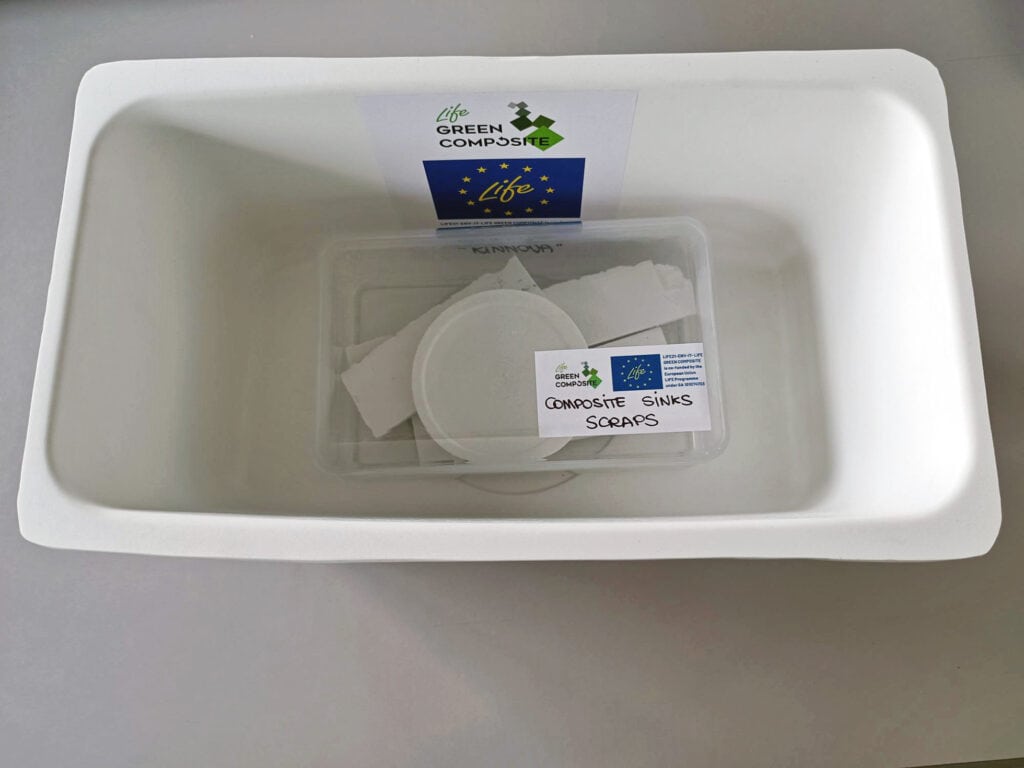

Grinding one composite sink waste and scraps and production GREEN

Using new milling and coating technologies, new product design and pre-polymerisation, new product design and pre-polymerisation, reuse of production waste from these sinks to improve the performance of recycled composite tops and panels.

WORK PACKAGE defined to achieve objectives:

| Work Package No | Work Package name | Lead Beneficiary |

| WP1 | Project management and coordination | 1-DELTA SRL |

| WP2 | Recovery of mineral materials from waste sinks and preparation of secondary raw materials | 1 - DELTA SRL |

| WP3 | Development of green kitchen tops that include recovered Delta sinks waste | 2 - GEES |

| WP4 | Development of green sinks: new formulations, moulding trials and characterisation of end products | 1 - DELTA SRL |

| WP5 | Communication and Dissemination of results, networking | 1 - DELTA SRL |

| WP6 | Sustainability, Replication and Exploitation of Results | 1 - DELTA SRL |

| WP7 | Performance indicators and impact monitoring and evaluation | 1 - DELTA SRL |

Pilot and industrial scale trials will be conducted by recovering mineral materials from waste sinks, which will become secondary raw materials to develop green kitchen countertops and green sinks.

New Industrial Plants

A new grinding plant will be developed, which will carry out the volumetric reduction of sink scraps and waste to obtain the secondary raw material.

A green plant will be installed, consisting of a recovery resin storage tank and reactors for convertingone the recovery resin into recovery syrup.

Recovery charges for new dispersions (r-quartz and r-granulates)

Innovations

DELTA: New formulations with secondary raw materials, obtaining GREEN sinks;

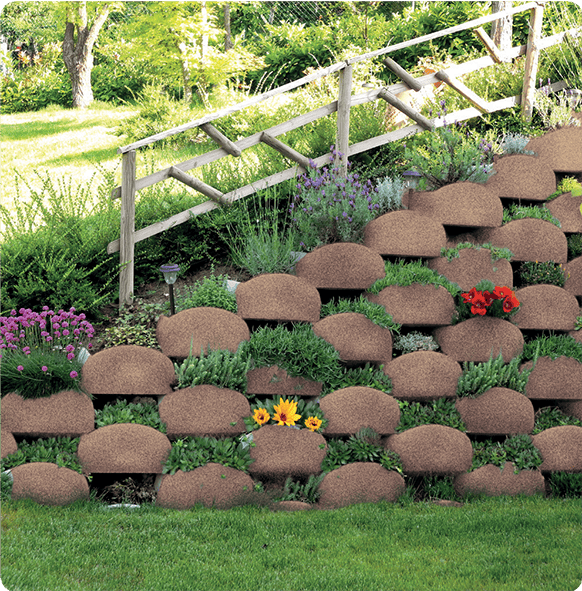

GEES: New work tops with GREEN formulas using secondary raw materials;

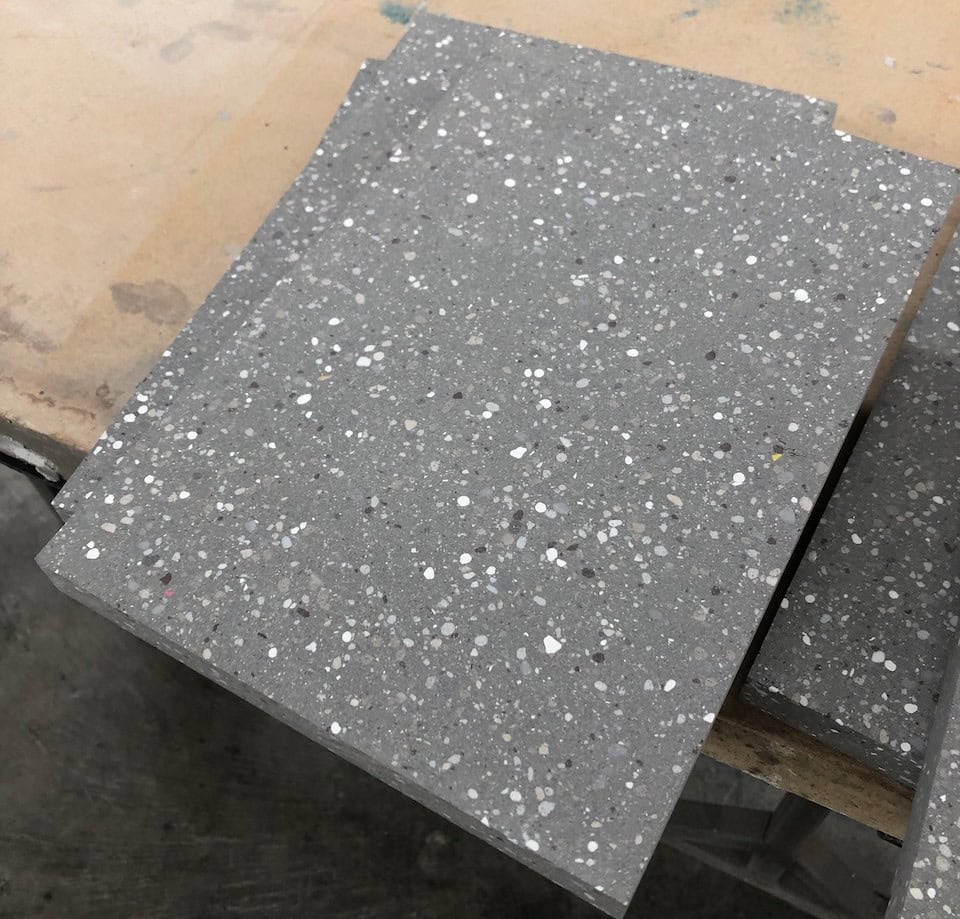

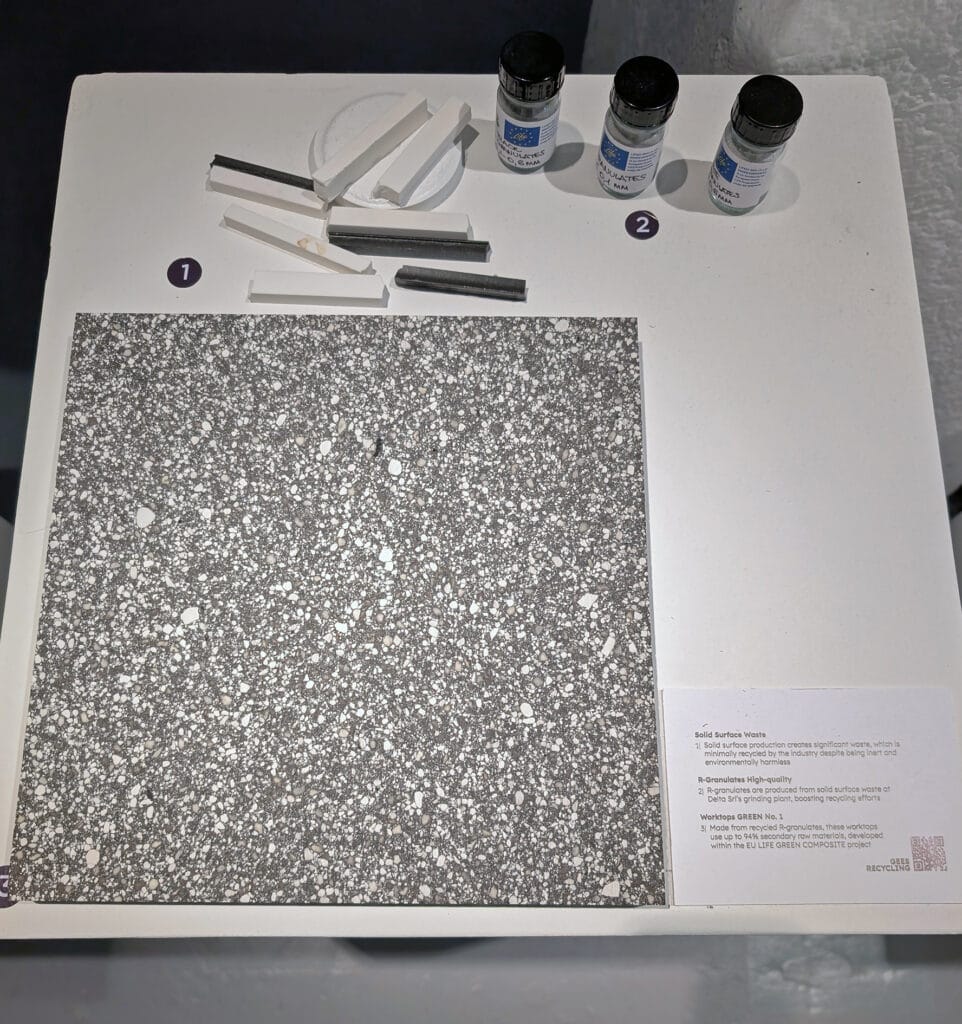

Gees is pursuing the mechanical recycling of high-density composites. Initial tests were carried out on the following composizione:

75% of r-granulates (ground DELTA composite sinks)

- 20% of waste glass fibre;

- 5% of binding agent.

The density of the first GREEN sample panel No. 1 is 1250 kg/m3

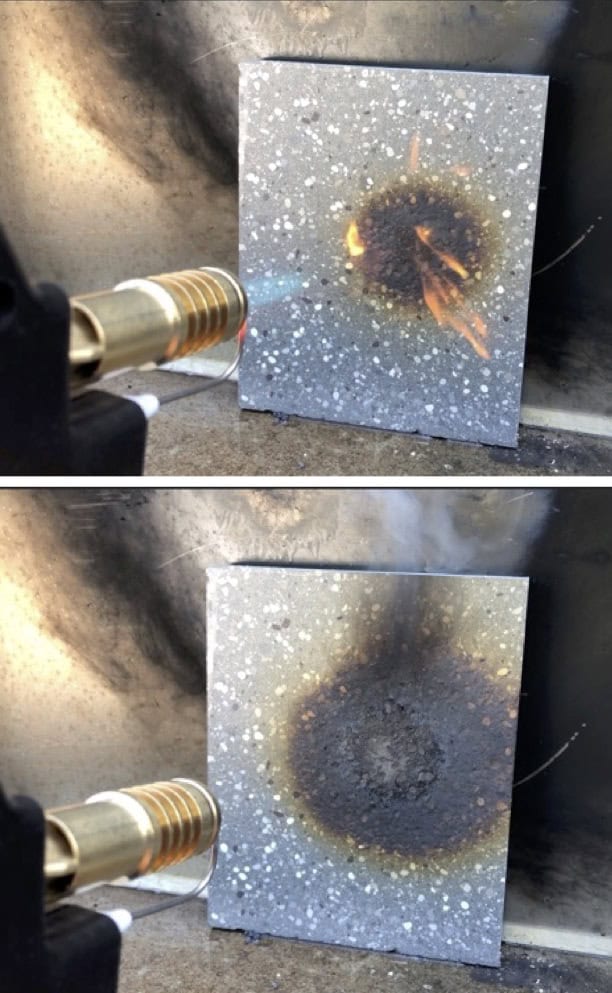

Initial tests are showing good fire behaviour potential of recycled composites. The first GREEN fieldsone panel No. 1 showed no dripping, no post-combustionone and no perforationone after 2 minutes of feedingone a propane flame at a distance of 10 cm

Impacts

Recycling the 100% of waste and scrap from the Plados Telma group to enable the productionone and commercialisationone of a green sink production line made entirely from recycled materials.

Launching both solid-colour and granite-effect composite worktops on the market with a new concept productone with improved performance, made entirely from recycled materials.

LIFE21-ENV-IT-LIFE GREEN COMPOSITE

Interviews on recovery and circular economy

Downloadable material

D 6.1 Feasibility Study on the recycling of end-of-life composite sinks

Life Green Composite project poster

Life Green Composite Project Brochure

- 01 August 2022

- 18-21 October 2022

- 10 January 2023

- 07 February 2023

- 16 February 2023

- 15 March 2023

- 16 March 2023

- 17 March 2023

- 23 March 2023

- 17 April 2023

- 09 May 2023

- 01 June 2023

- 17 October 2023

- 06 December 2023

- 10 January 2024

- 16 January 2024

- 06 March 2024

- 20 March 2024

- 22 March 2024

- 15 June 2024

- 04 September 2024

- 08 October 2024

- 15-18 October 2024

- 06 November 2024

- 10-12 February 2025

- 06 April 2025

- 11 April 2025

- 12 April 2025

- 23 April 2025

- 13 May 2025

- 26 May 2025

- 04 June 2025

- 4 June 2025

- 20 June 2025

- 20 June 2025

- 03 July 2025

- 04 July 2025

- 20 July 2025

- 28 July 2025

The project officially starts after the Grant Agreement is signed by Plados Delta and the European Comissione at the end of July 2022

From 18 to 21 October 2022, Plados Telma participated as an exhibitor at the SICAM trade fair in Pordenone (Italy).

The LIFE GREEN COMPOSITE team took the opportunity one to present to the market and its customers a first prototype of 100% green sinks, in the colour WHITE, not yet aesthetically perfect, but made from recycled raw materials, from resin to mineral filler. This prototype is one of the sinks produced during the moulding trials that showed the best results for sinks in this colour. In the coming weeks and months, the project team will focus on producing one more colours and perfecting the white sinks. Visitors to the stand were very interested in the quality of the sinks made from recycled materials, as well as the difficulties they encountered in finding them. They also asked informaions about the colours that will be available in addition to the white presented, and were curious as to whether the cost would be much higher than that of sinks made from virgin raw materials.

On the one hand, this trade fair confirms the reputation now acquired by the Plados Telma brand, which has sales partners in 60 countries on five continents, and on the other, it confirms the market's interest in the new green sinks.

The SICAM trade fair in Pordenone (Italy) was attended by 10,000 companies from 120 countries. The Plados Telma stand was visited by 2,000 visitors, kitchen accessories distributors, kitchen manufacturers, trade intermediaries, suppliers, designers. 300 new contacts were generated from around 30 countries.

Presented the official logo of the Life Green Composite project!

The Life Green Composite project brochure has been created. It contains a graphic representation of the project structure that follows the principles of the circular economy, immediately attractingone attention.

Project Notice Board posted at the main entrance of the Delta site in Montecassiano (MC) and Montelupone (MC) and at the main entrance of the GEES site in Aviano (PN). The Notice Board shows the key informaions of the project in a visually attractive graphic, which emphasises the circular economy structure of the project activities.

Picchio News published a press release on the LIFE GREEN COMPOSITE project 'The Plados-Delta group will be the first company in the world to produce a range of 'green' sinks'

A press release on the LIFE GREEN COMPOSITE project published in Cronache Maceratesi "The first 'green' kitchen sink is born in the Macerata area'.

Lavello Green will be born in the Macerata area

Visit of a delegation one Delta to the company HP Composites S.p.A. for a mutual acquaintance and synergy between 2 companies working in the world of composites.

Present from Delta were Antonio Bugiolacchio, Leonardo Bugiolacchio and Maria Savina Pianesi; from HP Composites Vincenzo Castorani.

Delta presented the LIFE GREEN COMPOSITE project: eco-friendly kitchen sinks and worktops: harnessing industrial symbiosis to produce acrylic mineral composites from recycled and traced production waste in a replicable circular value chain.

The objectives of the project were described, i.e. to make new green sinks from external and internal production waste, suitably ground, coated and combined with a new acrylic resin from converted monomer, as well as to make worktop panels with improved performance by recycling production waste from sinks.

HP Composites told us about the 3 projects the company is currently in charge of.

The first LIFE CIRCE - CIRcular economy model for Carbon Fibre Prepregs (https://www.life-circe.eu/) is closing in April 2023. CIRCE is a circular economy project set up to develop a new recovery system for industrial waste from carbon fibre prepregs. The main objective is to establish a circular economy model for uncured waste.

The second project called LIFE VIABLE - Valorizazione of lignin biomass in competitive compones gradually replacing BPA in the formulation of epoxy resins (https://www.life-viable.eu/) started in 2021 and will close in 2025. The project aims to improve the sustainability and environmental impact of epoxy resin production by reducing the BPA content in the formulation of epoxy resins from 20 to 50% through lignin biomass.

The third and last called PLOOTO - Product Passport through Twinning of Circular Value Chains (https://cordis.europa.eu/project/id/101092008) has just started and will last until 2025. Plooto aims to provide a circular and resilient informative system (CRIS) to support manufacturers in their green, digital and circular transition. CRIS enables waste reduction and end-to-end traceability of secondary raw materials (SRM) through interconnected digital services for real-time decision-making, monitoring and certification of materials and products. It is funded by the Horizon Europe programme.

The same common problems related to material waste, the difficulty of recovering such heterogeneous materials, and the high cost of disposing of them.

There was a very interesting visit to the production departments, where racing car bodies and automotive facilities are produced.

We promised to discuss again to define the possibility of solving common problems, and as a first meeting at the MARLIC project progress meeting planned for June 2023 where HP is the lead partner of more than 20 partners, Delta will present the LIFE GREEN COMPOSITE project to all.

Plados Telma participated as an exhibitor at the Interzum trade fair in Cologne from 9 to 12 May 2023.

It met and showed its customers the first recycled sink prototype in the colour WHITE, obtained from the one experiment financed by the LIFE GREEN COMPOSITE project. Plados Telma has commercial partners in 60 countries on 5 continents; many of these visited the stand and were able to touch the new product proposed under the trade name ?Rinnova?

The Interzum exhibition had 1,400 exhibitors, was visited by 74,000 visitors from 152 countries and had an exhibition area of 190,000 m2. The Plados Telma stand had around 1,500 visitors and generated 150 new contacts from around 40 countries. During the fair, the Plados Telma sales team met a selected number of new contacts, presented the LIFE GREEN COMPOSITE project to them and handed them project flyers and small samples of sink surfaces in white and beige. Seven retailers, wholesalers and manufacturers from various countries (in addition to Europe, also Mexico, Mongolia,

UK and Albania) were very interested and asked to be kept up-to-date on product development, indicating their intentionone to introduce the new products in their catalogues once they are commercially available.

At the end of the progress meetingone of the regional project MARLIC (acronym for Marche Applied Research Laboratory for Innovative Composites), a regional collaborative flatforma on the topics of sustainable manufacturing, eco-sustainability, processes for new composite materials and de-manufacturing, on 01-June 2023 Dr. Pianesi, R&D Manager of the Delta company and de-manufacturing project leader, presented the new LIFE GREEN COMPOSITE project to all project partners: HP Composite, Simeg Marmi, Simeg Fratelli Marmi and the project leader.ssa Pianesi, R&D Manager of the Delta company and leader of the de-manufacturing project, presented the new LIFE GREEN COMPOSITE project to all the project partners: HP Composite, Simeg Marmi, Fratelli Guzzini, Simonelli group, Mailas, Eta, and to the entities Università Politecnica delle Marche, Università degli studi di Camerino, Università degli studi di Urbino, CNR, Enea.

The greatest interest was focused on the possibility of being able to cross-use this composite recovery in other applications, especially in the world of composite racing car structures.

At SICAM 2023, the International Trade Fair of Componenents, Accessories and Semi-finished Products for the Furniture Industry, you will find all the latest news and market trends for future collections of furniture, kitchens, bathrooms, contract and interior design. From 17 to 20 October rinnova the appointment with the international fair, now in its 14th edione with over 18 thousand net square metres and 650 exhibitors.

Delta of the Plados Telma Group, winner of the LIFE GREEN COMPOSITE project, presented the first prototype sinks in white, beige and grey. The prototype sinks made from recycled raw materials have been a resounding success. We hope to extend these results to the production of a new green range as soon as possible.

The SICAM fair had 650 exhibitors, 8,900 visitors and an exhibition area of 18,000 m2.

The Plados Telma stand at the SICAM 2023 exhibition had about 1500 visitors and generated 150 new contacts from about 40 countries. During the fair, the Plados Telma sales team met about 50 customers, presented the LIFE GREEN COMPOSITE project to them and handed them project flyers and small samples of sink surfaces in white and beige. Around 35 customers, including traditional Italian customers such as ARREDO 3, SCAVOLINI / ERNESTO MEDA, CEDI and other customers from various EU countries and the Middle East, asked to be informaed about product developments and indicated their intentionone to include the new products in their catalogues once they are commercially available.

Delta's new composite sink waste and scrap grinding system has been launched. From today it will be possible to recover all material and no longer send it to landfill!

First electron microscope photos of the milk-white sink ground by our newly started-up frazione r-quartz r-quartz system. Image: photomicrograph of the 0.1 mm frazione r-quartz white

First tests of millingone waste and rejects from white sinks in our new milling systemone. Image: Fieldsone r-quartz in different grain sizes white Delta

Article 'MARLIC LIFE GREEN COMPOSITE' of 06/03/24 in the Green and Blue insert of the newspaper 'La Repubblica'.

Publication of the video 'Life Green Composite - Rinnova':

Second EU monitor meeting in Delta Plados the brilliant results achieved, the installation of the green plant and the grinding plant were shown to the EU monitor and the next steps were discussed.

The LIFE GREEN COMPOSITE project was presented at the CHIP Department of Chemical Sciences in Camerino during the 4th Chemistry Graduates' Meeting Day.

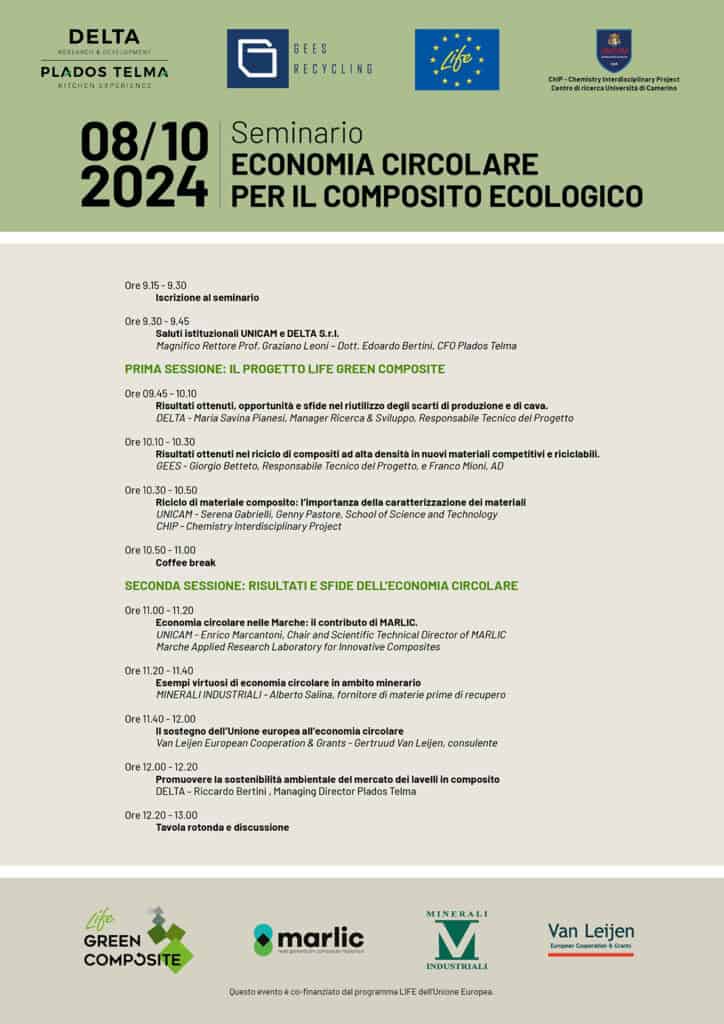

Delta S.r.l. of the Plados Telma Group is preparing the Seminar of the European project LIFE GREEN COMPOSITE that will be held on the morning of Tuesday, 8 October 2024, starting at 09:15 a.m. in the press room of the ChIP of the University of Camerino.

Professionals and experts will participate and present their experience and results of the project in order to stimulate a dialogue with the industrial world active in the composites sector and on the topic of green recovery. The morning programme is attached.

The seminar of the LIFE GREEN COMPOSITE project, organised by Delta Plados Telma and Gees Recycling, at the University of Camerino UNICAM Chip was an opportunity to compare and discuss approaches to sustainability in the field of composite materials.

Interesting insights and complex experiences shared to achieve a common result: the reduction of waste sent to landfill. We would particularly like to thank all the speakers for their valuable contributions and all the guests who spoke.

Exposureone of the products at the SICAM trade fair in Pordenone and incredible customer interest in the materials studied in the LIFE GREEN COMPOSITE project.

On 6 November 2024, the LIFE GREEN COMPOSITE project was presented at Ecomondo by Delta srl of the Plados Telma Group, with speaker Maria Savina Pianesi and Giorgio Betteto of GEES RECYCLING. In the Mimosa room of the ECOMONDO section ?Supporting the transition of Italian industrial and brown areas into eco-industrial parks and the implementation of industrial symbiosis as a routine management tool for companies? Delta described the green transition and industrial symbiosis that is taking place between Gees and Delta. The large audience in attendance attended and followed the seminar attentively, with requests for details and questions.

CINEA invited Delta to the LIFE Platform Meeting on plastic waste preventionone and reuse systems, organised by the Belgian LIFE-IP project C-MARTLIFE.

Delta presented the LIFE GREEN COMPOSITE project poster. Interesting synergy between the various projects met with Life green composite led by Delta Plados and strategic partner Gees Recycling from 10 to 12 February 2025 in Brussels.

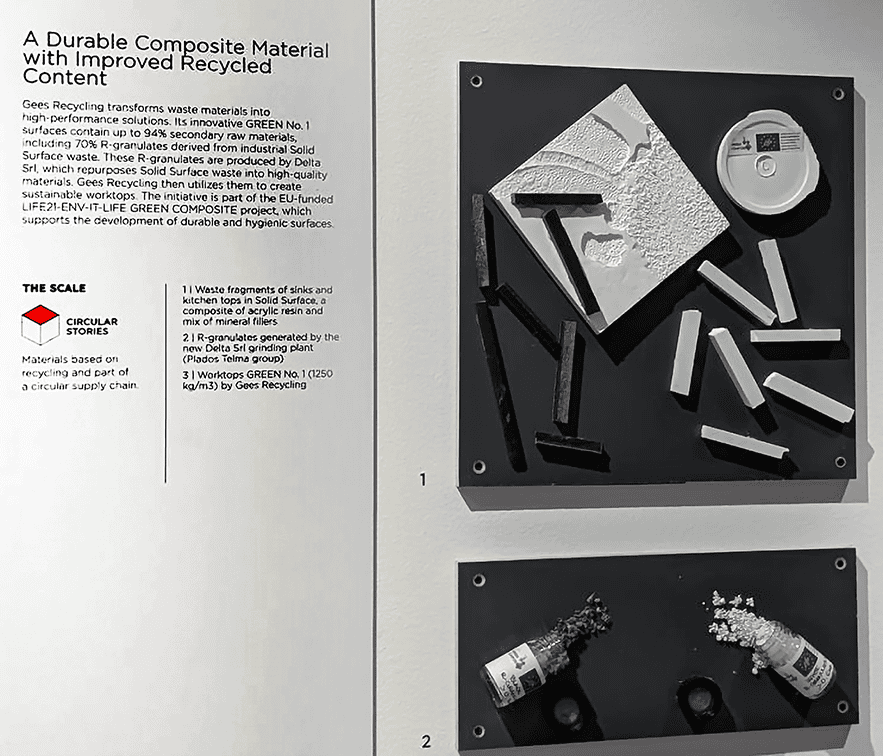

The LIFE GREEN COMPOSITE project, in collaboration with Materially, will take part in the event The Scale of Commitmentan initiative that enhances the concrete commitment of material producers

in pursuing measurable results in terms of reducedone environmental impact and improved performance.

We look forward to welcoming you at spazio at Superstudio Più, via Tortona 27 - 20144 Milan. The event will be open to the public from 6 to 13 April 2025, on the occasion of the @Milano Design Week.

The communication of Delta, part of the Plados Telma Group and Gees Recycling - partners in the project - will be entirely dedicated to LIFE GREEN COMPOSITE.

On displayone: samples of sink scraps and a sink green of the RINNOVA line, in the refined Arctic White finish.

Publicationone of an article on the Life Green Composite project on the polimerica.it portal

LIFE GREEN COMPOSITE, an industrial symbiosis project between Delta of the Plados Telma Group and Gees Recycling is present at Milan Design Week!

We are pleased to announce that the results of the LIFE GREEN COMPOSITE project have been published on the website of the Ministry of the Environment and Energy Security. In sectionone dedicated to 2025 news, you will find an in-depth look at the progress and innovations our project has made in the context of the LIFE Programme. Our commitment to a circular and sustainable economy has been recognised nationwide, and we are excited to share these achievements with you.

Delta was invited to the CINEA stand at Green Week to present the results of the LGC project. Sample sink scraps, a green sink and r-granulates will be shown.

SAVE THE DATE!

The final conference of the project is scheduled for 10 July at the Urbani Hall of the University of Camerino.

Plados participates in European Green Week by presenting the Life Green Composite project:

https://www.pladostelma.com/uncategorized/plados-alla-green-week-2025/

Publication of the second project brochure:

Publication of the programme for the final seminar on 10 July.

The magazine 'Polimerica' publishes an article on the final conference of the Life Green Composite project: https://www.polimerica.it/articolo.asp?id=34091

The LIFE National Contact Point Team published the news of the final LIFE Green Composite seminar on the website of the Ministry of Environment and Energy Security and disseminated it through social channels.

https://www.mase.gov.it/portale/web/guest/-/notizie-life-2025-

Publication of Layman's report:

With great satisfaction we share the success of the final seminar of the LIFE GREEN COMPOSITE project promoted by Delta of the Plados Telma Group and @GeesRecycling, which took place on 10 July at the University of Camerino (UNICAM).

The event represented an important opportunity to discuss and share the results achieved by the project, aimed at the development of sustainable, innovative and circular composite materials. Keynote speeches, valuable technical content and stimulating round table discussions enriched the day, confirming the importance of collaboration between companies, academia and institutions.

📌 The project was co-financed by the European Union through the LIFE programme in support of ecological transition.

Many thanks to all participants, speakers and partners involved: your contribution made this event a real success.

🔗 Read more about the project: https://lnkd.in/dhGbnuTc

LIFEGreenComposite #PladosTelma #GeesRecycling #UNICAM #PProjectLIFE 1TP77Sustainability #EconomyCircular #Innovation #Research 1TP77Ecological Transition

LIFE GREEN COMPOSITE: 'Green' Sinks and Panels on the Market!

The LIFE GREEN COMPOSITE project by Plados Telma (Delta S.r.l.), Gees Recycling and the University of Camerino (UNICAM), co-funded by the EU, ended with the final seminar held on 10 July 2025 in Camerino.

The event celebrated the success of the three-year project, which led to the production of 'green' sinks and panels on an industrial scale, made from entirely recovered waste and resins. Thanks to a new milling plant and an innovative production line, this industrial symbiosis has enabled the launch of the 'Rinnova' range (already in 70 countries) and paved the way for new applications in sectors such as automotive and design.

Watch the video and interviews from the final seminar:

LAYMAN'S REPORT

With great enthusiasm, we are pleased to present the Layman's Report of our project. This document encapsulates in a clear and accessible way the concrete and measurable results we have achieved, confirming the enormous potential of our work for the circular economy. We invite you to download the PDF to find out how we have transformaed waste into valuable new resources, contributing to a more sustainable future.

FINAL RESULTS OF THE PROJECT

The success of the LIFE GREEN COMPOSITE project is not limited to the production of 'green' sinks and panels, but opens up new perspectives for the adoption of a circular model in other contexts and for the valorisation of end-of-life materials.

1 - EVALUATIONS ON THE USE OF QUARTZ

BY RECOVERY IN THE MANUFACTUREONE OF SINKS

(D4.1 Report on the use of recovered quartz)

As characterised, the prototype green sinks with

r-quartz have a quality quite comparable to the traditional sink line made from virgin materials and are therefore marketable. In contrast, the prototypes of green sinks with

r-granulates are a less reliable, durable and overall less suitable choice for the wear resistance requirements of the kitchen environment. While the use of a low percentage of r-granulates and the combined use of r-quartz resulted in sinks with a better aesthetic appearance, the improved mouldability also led to a slight decrease in the mechanical properties of the product, as a result of the reduction in mineral filler and the increase in acrylic resin and additives.

One must also consider the problem of the higher cost of the formula with r-granulates, as it is very different, which obviously influences the decision to market it. The cost of the sink formula with r-granulates is 44% higher than that with r-quartz, due to the higher amount of acrylic needed to wet the r-granulates recovery charge. After evaluating all technical, performance and economic aspects, only the green sink line with r-quartz was launched on the market, called RINNOVA in 4 colours: Arctic white, Dune beige, Alp stone, Volcano black.

2 - CHARACTERISATIONONE OF GREEN MATERIALS

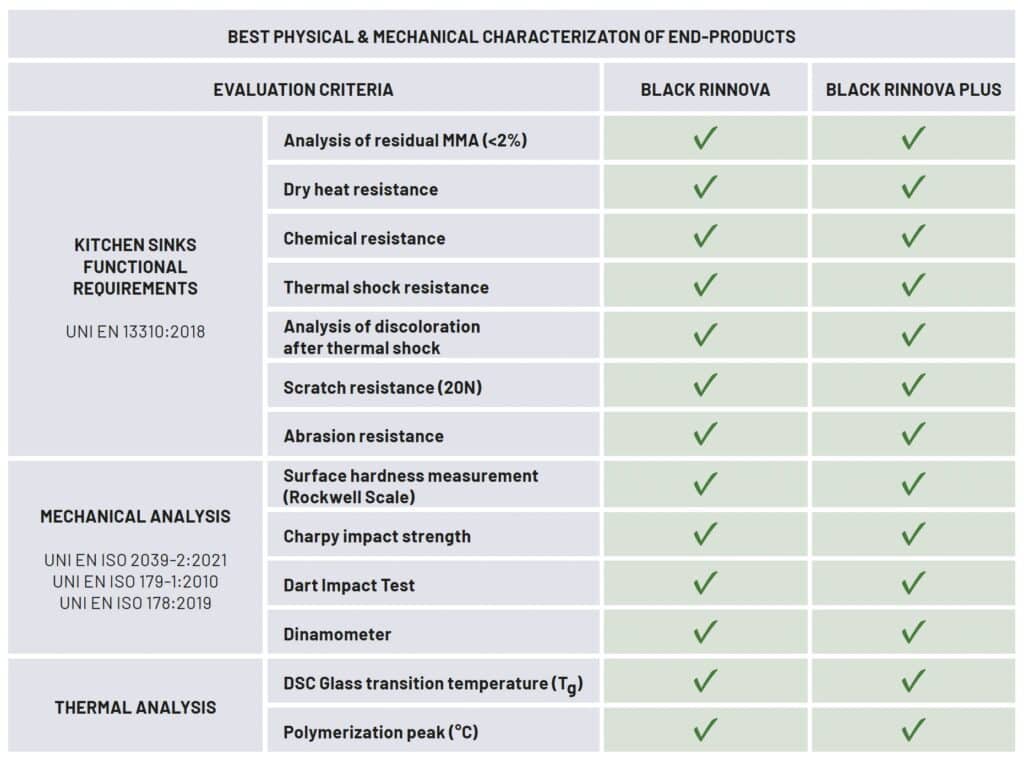

(D 4.3 Report on the performance of Green Sinks)

New industrial processes for RINNOVA green sinks were tested and refined through experimental campaigns. The objectives included the selection of optimal waste particle sizes (r-Granulates), the refinement of the conversion of the r-MMA monomer into r-Syrup, the optimisation of green formulations for sinks and panels, and the improvement of moulding. Through these tests, the best green formulations with more than 95% of recovered materials were developed and characterised in the laboratory to the required standards. 'Characterisation' means subjecting products to a series of specific tests to measure and evaluate their physical and chemical properties. For example, impact resistance, durability, reaction to liquids and detergents, or aesthetic appearance are tested. This process allows us to ensure that the final product is of high quality, reliable and meets all requirements, especially when using new formulations with recovered materials. In essence, it is our way of confirming that 'green' products work as well as, if not better than, traditional ones.

3 - MARKET STUDY AND BUSINESS PLAN

(D 6.5 Marketing study and business plan)

Market analysis has shown a favourable context for the diffusion of sustainable solutions in the kitchen furniture sector, with an increasing focus by consumers, distributors and manufacturers on recycled, traceable and ESG-compliant materials. Delta has positioned itself distinctively with a unique product: a sink made from 95% recycled materials, with no compromise in terms of performance, aesthetics and durability. This competitive advantage, combined with a targeted marketing strategy and an established distribution network, allows the company to confidently face the challenges of the market and seize the opportunities offered by the ecological transition. Economic and financial projections outline a sustainable growth path, with a progressive increase in production and margins, driven by the green line. Although initial volumes are lower than forecast, the positive feedback from some key markets (Northern Europe, Australia, France) confirms the validity of the proposal and the need to continue with targeted investments in communication, formaion and range expansion.

The Rinnova line represents not only a product innovation, but also a strategic evolution for Delta, which strengthens its commitment to a circular, competitive and responsible industrial model. This plan constitutes a concrete basis for attracting new partners, accessing green financing and guiding the company's futura growth while respecting the principles of environmental and economic sustainability.

4 - COLLECTION EVALUATIONS

SINKS END-OF-LIFE COMPOSITE

(D6.1 Feasibility study on the recycling

of end-of-life composite sinks)

The post-consumer collection of sinks is technically feasible, allowing the recycling of materials and the reduction of landfill. The results of the study on the feasibility of recovery can be summarised as follows:

- Recyclability: Composite sinks are technically recyclable by mechanical processes. The materials obtained can be reused in various sectors.

- Environmental benefits: Recycling reduces landfilling and enables the recovery of raw materials

- Operational ObstaclesThere is a lack of adequate collection infrastructure; transport and storage costs are significant; stakeholder participation requires shared governance.

- Economic feasibilityPre-consumer recycling is competitive with disposal, while post-consumer recycling will have to be economically evaluated, as it presents greater variability, costs and logistical issues.

The project laid the foundations for a promising circular model with a concrete potential for sustainable end-of-life sink management, if economically implementable.

5 - DISSEMINAONE AND PRESENTATION FAIRS

OF THE RESULTS OF THE LIFE GREEN COMPOSITE PROJECT

(D 5.5-Final Dissemination Pack)

During the SICAM and INTERZUM trade fairs in which DELTA participated, around 500 new business contacts were generated, including around 50 potential customers who expressed interest in the new product 'RINNOVA'. The presentation of DELTA and GEES at ECOMONDO was followed with great interest by more than 250 stakeholders from the recycling industry. Following the contacts made during the fair, meetings were planned with several companies to show them the LIFE GREEN COMPOSITE plants and to evaluate new projects in the recycling and waste recovery sector. The activities and results obtained provide a promising basis for the market of new green sinks and green panels and open up a potential expansion of the applications of recovered materials.

6 - ENVIRONMENTAL IMPACT OF THE PROJECT

(D7.2 PEF report)

The LIFE GREEN COMPOSITE project has achieved concrete and measurable results, demonstrating the effectiveness of our circular economy approach through the PEF report, a European methodology for analysing the environmental impact of a product throughout its entire life cycle. The adoption of recycled raw materials instead of virgin ones has generated a significant positive impact on multiple environmental indicators, going beyond just reducing CO2. We recorded important decreases in key categories:

Acidification: -72%

Land use: -20%

Water use: -56.5%

Ecotoxicity: -50%

Overall, the project avoided the consumption of significant amounts of virgin materials during its lifetime, replacing them with recovered materials:

r-MMA, r-Syrup and Chemicals: 150 tonnes

r-Quartz and r-Microsphere: 108 tonnes

r-Granulates (for Delta use): 12 tonnes

r-Granulates (for Gees use): 217 tonnes

The enormous potential of r-Granulates has been confirmed by

a comparative analysis: the comparison between 1 kg of virgin quartz and 1 kg of

r-Granulates showed a drastic average reduction of 85% in Global Warming Potential (GWP), expressed in CO2eq. This opens the way to many new industrial applications where granulate can replace virgin materials.

7 - PRESENTATIONONE OF PROJECT RESULTS

LIFE GREEN COMPOSITE AT THE FINAL CONFERENCE

(D5.4 Final conference)

It was a very interesting time to share results and issues, especially during the working table on by-products; in particular, the issue of the current quantities of available granulated waste (r-granulates) compared to potential uses and that of the price, which should be aligned with the cost of quartz, its possible substitute, emerged. Worthy of note were the possible synergies that were highlighted among the seminar participants, and the concrete prospects for further development of research projects by exploiting the results and experiences of Life Green Composite.