The Story of Plados Telma

Since 1991 with stepsone and innovaone.

Plados S.p.A. is founded, with the aim of producing kitchen sinks in composite material. In a short time, the company manages to conquer an important position in the international scenario.

Inauguration of the new headquarters in Montecassiano (MC) of about 10,000 square meters.

The companies PLADOS and TELMA (the latter, born in 1981, was the first Italian company to produce composite sinks) join their forces and experiences, giving life to one of the most advanced production centres of composite material sinks in the world.

Plados-Telma Group is the first company in the world to propose the antibacterial sink able to inhibit the development of microorganisms, thanks to the use of silver ions.

Inauguration of the new raw material production plant, developed with cutting-edge technology and fully automated. The facility has a total surface area of 3,500 square metres.

ARIAPURA: The sink that breathes.

Plados-Telma group presents the sink that helps to purify the air in the kitchen environment. Thanks to titanium dioxide nanoparticles and their photocatalytic action, ARIAPURA sinks can perform a triple action:- Anti-pollution

- Antibacterial

- Self-cleaning

The company obtains an important recognition from the European Commission. The Green sinks project (production of ecological sinks with recycled raw materials) has been approved and financed by the LIFE programme, the European Community's environmental fund. It is one of the 12 Italian industrial projects financed by Europe during the two-year period 2013-2015.

The raw materials involved in the production of composite materials are limited in quantity, and the production of kitchen sinks does not currently use recycled materials. Instead, Delta's innovative idea aims to produce a new line called GREEN SINKS to completely replace virgin raw materials with recycled ones. The recovery will be of two types, the first deriving from the scrapone of sinks and internal scraps and the second from the recovery of raw materials from other industrial productions. The replacement of mineral filler in composite sinks will bring a number of advantages:

- Preservation of the landscape by reducing mineral extraction;

- Reduction in consumption for transporting ore from abroad;

- Recycling of a wide variety of pre- and post-consumer waste;

? Reduzione of waste going to landfill;To learn more visit greensinks.com

Introducing nanoSTONE, the new Plados-Telma material with the best mechanical and aesthetic characteristics a composite sink can have. Thanks to innovative high-tech mineral fillers capable of bonding together in a three-dimensional lattice, the sink structure is reinforced from the inside.

30 years of stepsone, enthusiasm and dedicationone,

30 years of innovationone and design.

30 years of Plados.

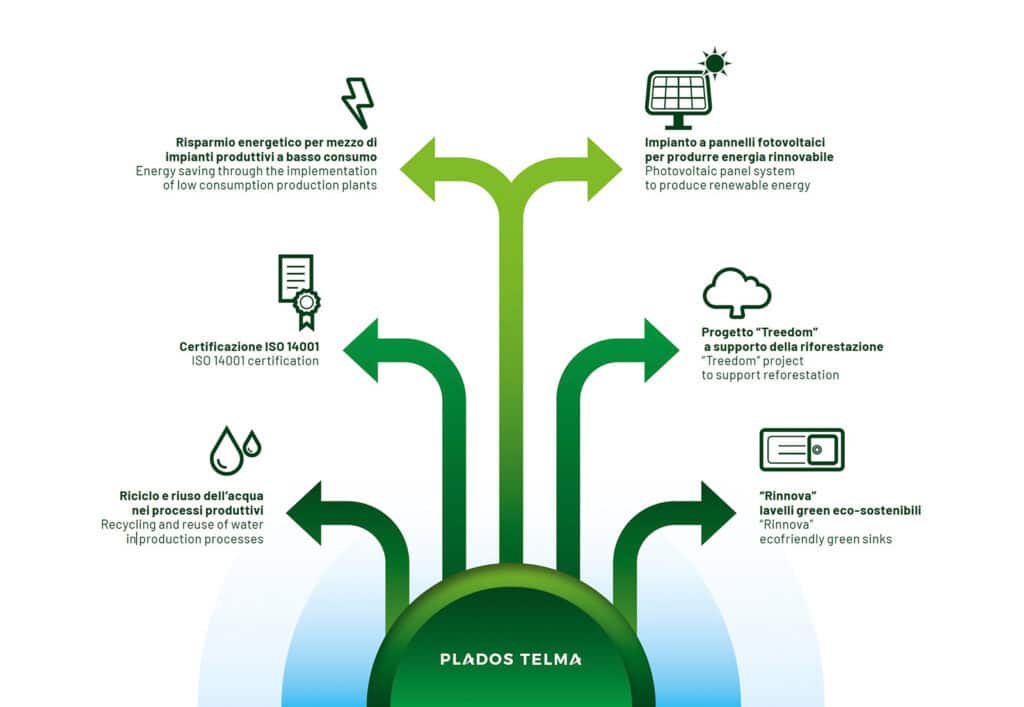

Rivoluzione Green

Nature, people and economy are the connected and interdependent terms of the same relationship; acting for the environment means generating growth in value for communities around the world. For this reason, Plados Telma's green commitment invests in the origin of the raw material, the production processes, the efficient use of energy and water resources, the product and the product life cycle, with the ultimate aim of building corporate sustainability.

RENEW: Renewed raw materials instead of virgin raw materials

Our aim was to maximise the use of organic (mma+pmma) and inorganic (mineral fillers) raw materials that would otherwise be destined for landfill, so as not to resort to non-renewable virgin raw materials. Through a process of regeneration of recovered raw materials, we obtained a green compound at the origin that guarantees the same chemical, physical, mechanical and aesthetic characteristics as the traditional compound of the Plados Telma sinks. The quality of the final product is identical, the difference is made by the origin of the raw material, a difference capable of being added value.

Visit the Rinnova page